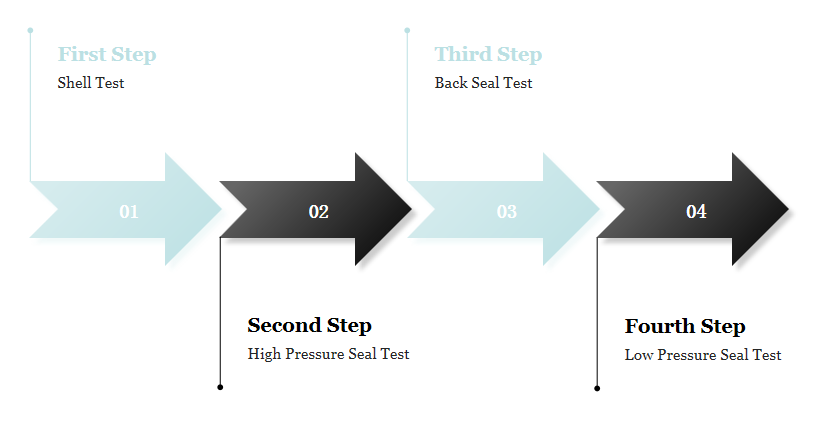

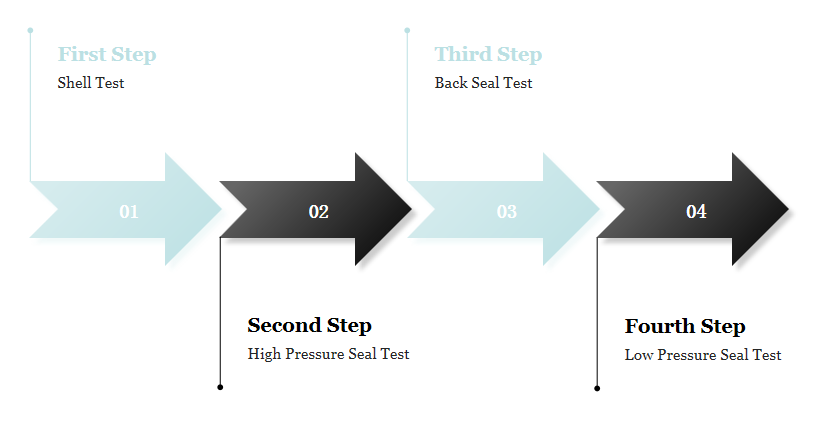

1. Experimental Items and Sequence

· Shell Test: 1.5 times the nominal pressure, to verify the strength of the valve body

· Sealing Test:

Gate valve: requires two-way testing (one end is pressurized, the other end is open)

Butterfly valve: when there is a flow requirement, the forward direction (1.1 times the pressure difference) and reverse direction (80% pressure difference) need to be tested

2. Leakage Rate Standard

| Type of Experiment |

Allowable Leakage Rate |

| Low Pressure Seal (Gas) |

Bubble Method Detection, No Visible Leakage |

| High Pressure Seal (Liquid) |

≤0.1ml/min(DN≤100) or ≤0.8ml/min(DN>100) |

API valve maintenance points

API valve maintenance points API Butterfly Valve Sealing Form

API Butterfly Valve Sealing Form What are the technical requirements of API valves?

What are the technical requirements of API valves? API 598 Testing Requirement

API 598 Testing Requirement Inspection Standard of API Valves

Inspection Standard of API Valves Performance of API flange butterfly valve

Performance of API flange butterfly valve