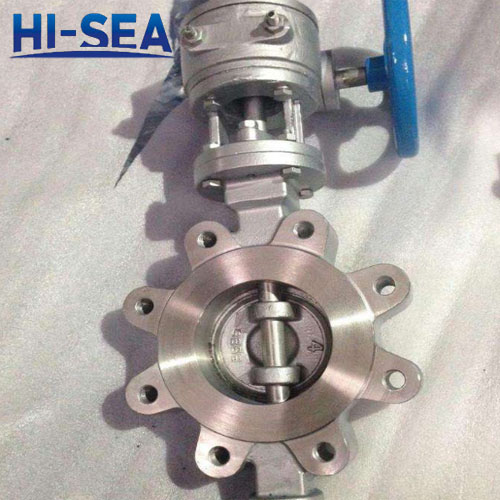

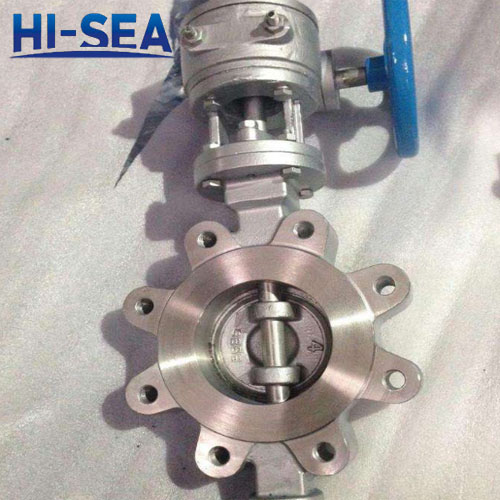

Valve body design:

Valve body material: usually cast iron (GG25), ductile iron (GGG40), carbon steel (WCB), stainless steel (CF8/CF8M) or duplex steel.

Sealing method: soft seal (rubber/PTFE): for low temperature and low pressure (≤150°C, PN16); metal seal (stainless steel + graphite): for high temperature and high pressure (≤600°C, PN40).

Butterfly disc design:

Material: 316 stainless steel, duplex steel (2205/2507), nickel-aluminium bronze (C63000), etc., need to be selected according to the medium.

Structure: Concentric butterfly valve (Centric): the valve stem is located in the centre of the butterfly plate, suitable for low pressure; Eccentric butterfly valve (Eccentric): single eccentric, double eccentric or triple eccentric design, reduce friction, improve sealing, suitable for high pressure conditions.

Stem design:

Material: usually stainless steel (416/17-4PH) or duplex steel, need to be corrosion and wear resistant.

Connection: keyway or pin fixing with butterfly plate to ensure reliable torque transmission.

Test Requirements

| Testing Project |

Standard Requirements |

Application Situation |

| Shell Test |

1.5×maximum working pressure, holding pressure ≥3 minutes without leakage |

All Valves |

| Sealing Test |

1.1×maximum working pressure, holding pressure ≥3 minutes without leakage |

Soft Sealing Valves |

| High Pressure Gas Test |

6 bar air or nitrogen to detect air bubble leaks |

Critical working conditions (e.g. LNG) |

| Operating torque test |

Measurement of full on/full off torque to ensure actuator match |

Electric/pneumatic valves |

Typical application scenarios

Marine industry: seawater cooling system, ballast water valve (need corrosion-resistant materials such as duplex steel).

Petrochemical industry: oil delivery, chemical medium control (need fireproof design).

Water treatment: municipal water supply, sewage treatment (soft seal, low cost).

LNG / natural gas: low-temperature conditions (need to deep-cooling treatment valve).

What media are API valves suitable for?

What media are API valves suitable for? API Ball Valve: Classification of Ball Support Structure

API Ball Valve: Classification of Ball Support Structure Why are most API valves made of stainless steel?

Why are most API valves made of stainless steel? How to maintain API valves

How to maintain API valves Installation Precautions for API Valves

Installation Precautions for API Valves Introduction to API Low- temperature Valves

Introduction to API Low- temperature Valves