API valve refers to strict compliance with the American Petroleum Institute (American Petroleum Institute) to develop industry standards for the design, manufacture and testing of industrial valves. As the global energy industry’s most authoritative technical specifications, API standards cover the valve materials, structural design, pressure testing, sealing performance and other technical requirements of the entire process, is to ensure the safe operation of equipment under high-risk conditions, ‘Technical Bible’.

API standard system analysis

API core certification standards for valves include:

API 6D: pipeline valve special standards (covering ball valves, gate valves, check valves, etc.)

API 600: steel gate valve construction specifications

API 607/6FA: fire test standards

API 598: Valve pressure test specification

Valves certified by API must undergo:

Overpressure sealing test (1.5 times the rated pressure)

High/low temperature operating conditions simulation test

Fire resistance test (still sealing after 30 minutes of burning)

Spectral analysis of material composition

API Valve Core Benefits

Safety redundancy design

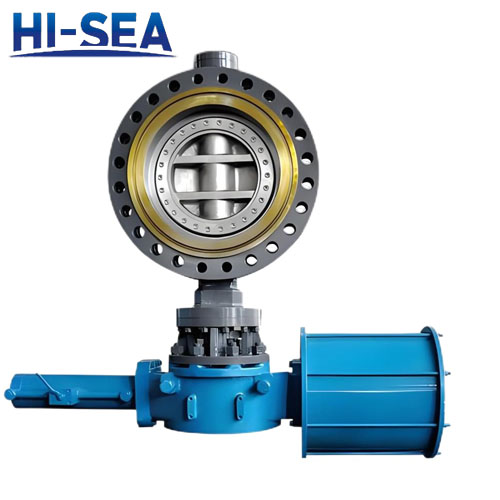

Adoption of longer valve stem, anti-blowout structure, double sealing system and other safety designs to prevent the risk of media leakage.

Stringent material requirements

The valve body is made of ASTM A216 WCB and other sulfur-resistant steel, and the sealing surface is overlay welded with Stellite alloy to adapt to H₂S acidic environment.

Intelligent operation and maintenance support

Sensor interface is reserved to support online condition monitoring and predictive maintenance.

Typical Application Scenarios

Oil and gas field production and transmission: wellhead unit, gathering pipeline

Refining plant: catalytic cracking, hydrogenation reaction unit

LNG receiving station: cryogenic shut-off valve, emergency shut-off valve

Offshore platforms: NACE MR0175 corrosion resistance standard.

What media are API valves suitable for?

What media are API valves suitable for? API Ball Valve: Classification of Ball Support Structure

API Ball Valve: Classification of Ball Support Structure Why are most API valves made of stainless steel?

Why are most API valves made of stainless steel? How to maintain API valves

How to maintain API valves Installation Precautions for API Valves

Installation Precautions for API Valves Introduction to API Low- temperature Valves

Introduction to API Low- temperature Valves